UNIWEX BIOMATIC STANDARD

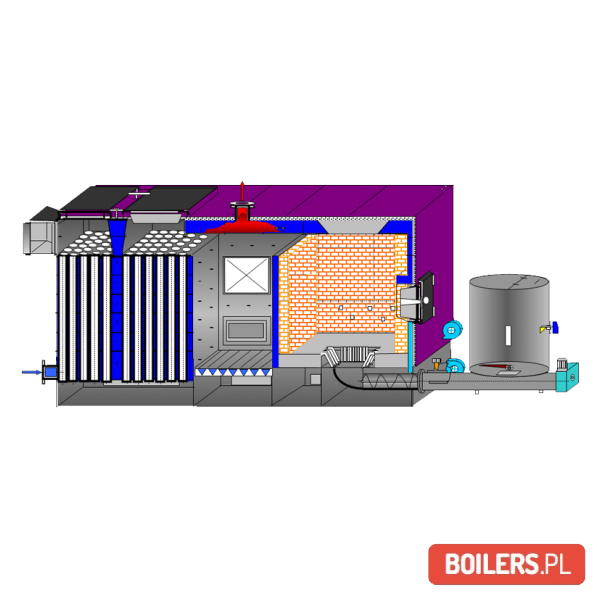

BIOMATIC Boilers are distinguished by an innovative solution whereby they are able to burn 10 types of fuel. They have two different hearths. They combine the advantages of both the feeder and the hopper models.

The boilers work in an open system.

The auto-feed mode allows the crushed fuel supporting the combustion process to be continuously transported to the hearth. Combustion takes place in a special, ceramic-lined chamber. This makes combustion of fuel containing a higher moisture content possible. The whole combustion process is fully automated.

In Traditional Combustion Mode chunks of wood and other solid fuels can be incinerated. Traditional, manual loading is carried out through an additional door. The furnace is equipped with a flat, water grid which, in turn, is incorporated into the device’s water circuit thus affording greater heat production.

In Automatic Loading Mode, the C.H. boiler is able to burn fuel having a moisture content of up to 50% upon reaching full rated power. The steel chamber has support function – allowing the achievement of 40% power. The chambers can operate independently or simultaneously.

In the BIOMATIC series, the heat exchanger is vertical, that is, tubular. This is achieved by varying the speed of the exhaust gases. This affects the efficiency of the device and, as a result, also has an effect on the best use of the heat energy from the exhaust. This solution has an advantage since only the minimum of ash is deposited in the exchanger’s tubes. The pipes are arranged vertically and thus the ash falls gravitationally into the ash-pan or cineraria below. This reduces the cleaning frequency of this element of the device.

Type of fuel:

Shredded: wood chips, sawdust, pellets, briquettes, wood-chippings.

Solid: lump wood, a mixture of wood and other fuels, ‘wood off-cuts’

BIOMATIC STANDARD SERIES

- comprises a group of low temperature boilers intended for open-system water installations

- work on natural air-flow

- highly efficient due to the vertical arrangement of the flues which maximise the thermal energy generated therein

- universal - combining features of both hopper and feeder boilers

- efficient use of the heat energy generated

- ceramic combustion chamber which accumulates the heat thus enabling consumption of fuels of higher humidity

- the ceramic combustion chamber is enveloped in a water jacket; this, in turn, keeps heat losses to the minimum

- automatic fuel delivery mode

- fully supporting manual feed mode

- boiler configuration adapted to the technical conditions of the boiler room

- retort burner

- fixed grate

- intuitive and user friendly control

- ecological burning, due to the vertical orientation of the exchanger, solid particles occurring in the flue gases are precipitated directly into the ash-pan

- easy cleaning of the boiler

- built from materials with enhanced durability

- external thermo-insulation

- possibility of adapting parameter configuration and accessories to the customer's requirements

- easy operation and maintenance

- the ceramic chamber ensures optimal and environmentally friendly conditions of combustion

- stable combustion process

- a thermostatic fire-protection valve

Pellets

Pellets  Biomass

Biomass Briquetted coal

Briquetted coal Wood

Wood Chips

Chips