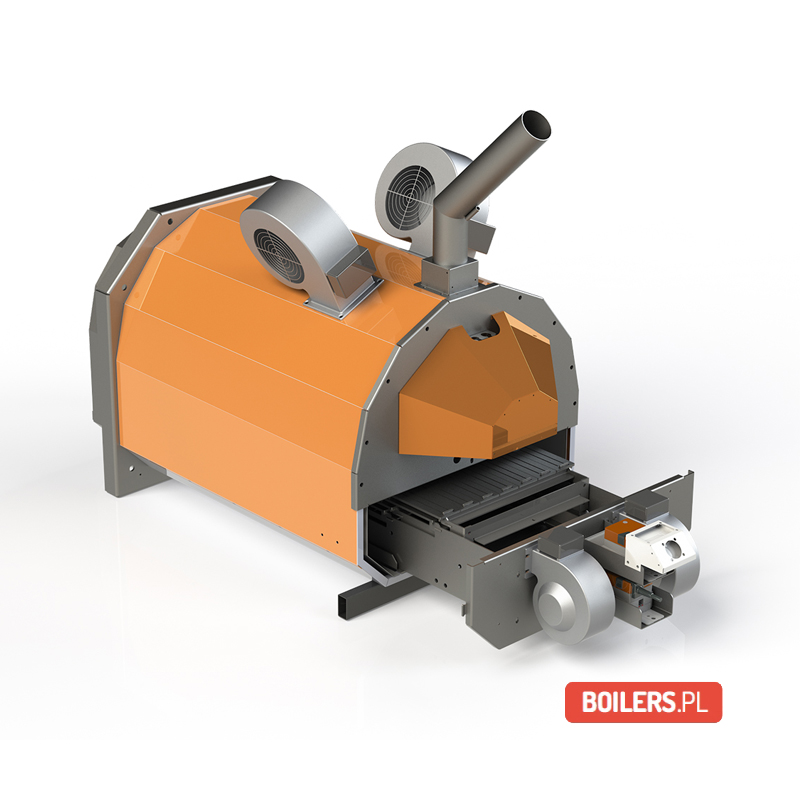

UNI-MAX ECO-BURNER

The ECO-BURNER in the UNI-MAX version is equipped with a segmented, moveable grate assembly in the form of a slide-out drawer for ease of cleaning; this solution is protected by patent.

It also has a ceramic insert which stabilises the conditions of the combustion.

Burners in the UNI-MAX series are able to burn almost any type of pellet available on the market, including good quality pellets such as those in the DIN, DIN+ classes and also industrial quality pellets, agro-pellets and fine, dry, loose biomass.

Advantages of the UNI-MAX ECO-BURNER:

- The heat-resistant, segmented steel grate ensures durability

- The stepped, moveable grate effectively empties the hearth of slag

- The burner starts and ends its operation with a clean hearth

- The ceramic chamber of the burner increases and stabilises the temperature of the combustion

- The patented air distribution system determines the quality and efficiency of the combustion

- Power modulation - the burner consumes only as much fuel as is required by the object being incinerated

- Step-less regulation of burning power in the range from 25% to 100% of the rated power

- Intended as a built-in fixture, the UNI-MAX ECO-BURNER does not require to be dismantled either for cleaning or for maintenance

- Over 50% savings when compared to heating with heating oil

- The Swiss-made, moveable grate drive comes with a 5-year warranty

- Reliable and durable equipment

- Low power consumption - energy class A+

Types of Fuel

Pellet

Includes

A complete burner with control, C.H. and D.H.W. sensors, wiring, a "spiro" pipe for connection to the burner with a feeder of standard length:

- 1.5m - for up to 40 kW burners inclusive

- 1.95m - 50-80 kW burners inclusive

- 2mb - 100 kW burners and higher

Feeders with direct feeding for lengths of up to 3m and supplementary feeders for fuel in tanks up to 6 m long are also available ensuring the automatic maintenance of the pellet level in the hopper

Rear Projection of the UNI-MAX ECO-BURNER

Pellets

Pellets