UNIWEX COMFORT PREMIUM

Water boilers in the COMFORT biomass version. This is a basic line in the portfolio of our Company. The following models are available: CLASSIC, CLASSIC RS, CLASSIC RT and PREMIUM.

Each model is well-suited to the heating of various industrial areas:

Carpentry shops

Carpentry shops

Drying rooms

Drying rooms

Warehouses

Warehouses

Greenhouses

Greenhouses

These are low-temperature devices for use in water systems - either open or closed.

Their advanced design ensures a wide selection of technical equipment with respect to fuel and any individual requirements of the user.

The most important advantages of these devices is their low fuel consumption and their high efficiency. Achieving such parameters is possible thanks to the use of the appropriate proportions in the heat exchanger’s surface. This maintains optimum combustion and increases the flow resistance of the exhaust gases.

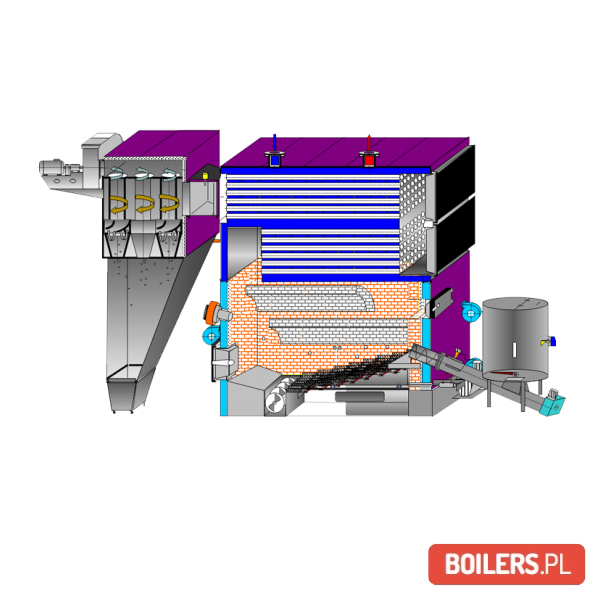

COMFORT PREMIUM BOILERS are modern facilities, constructed to be suitable for burning production waste, such as waste chipboard and such wood-based board as MDF and other kinds of biomass originating from forests, in accordance with the Regulation of the Minister of Economy and dated 21.03.2002 on the requirements for waste incineration.

The COMFORT PREMIUM Series

- ceramic furnace - so designed in order to retain combusted particles in the exhaust gases for at least 2 seconds at a temperature of not less than 850o C.

- ceramic ceiling - a double ceiling which additionally ensures that a fuel particle remains, for a protracted period of time, under conditions that allow its complete combustion.

- heaping/piling grill or grate, assisted by the hopper grill / incineration grate provides the right conditions for the almost 99% effective combustion and incineration of the material.

- 1500 kW boiler, equipped with a moveable grill as standard

- blast zones – the air blast zone ensures the optimum conditions for the thermal treatment process of post-production waste.

- oil burner - when necessary, the oil burner provides an extra boost of energy ensuring maintenance of the minimum required temperature of 850o C.

- the fuel feeding system - provides the right amount of fuel needed to obtain the boiler’s rated output.

- automatic ash removal as standard sensor of water temperature in the boiler

- exhaust gas cleaning multi-cyclone, system, which ensures compliance with the emission standards specified in the Regulation of the Minister of Environment of 04.08.2003 on emission standards from installation. The Multi-cyclone ensures a dust level of 80 mg / m3.

- temperature sensor provides continuous measurement of temperature in the combustion chamber.

- temperature sensor provides measurement of exhaust gas temperature.

- the Lambda Probe measures the oxygen content in the exhaust gas

- multi-cyclone exhaust gas fan provides sufficient negative pressure in the combustion chamber

- safety Thermostat

- thermostatic fire-protection valve

Additionally, the PREMIUM boiler’s functionality may be enhanced with the specific functions needed by the User such as, Internet connection for the remote control of the boiler’s parameters.

Pellets

Pellets  Biomass

Biomass Chips

Chips